Moving Bed Biofilm Reactor (MBBR)

Moving Bed Biofilm Reactor (MBBR) is an advanced wastewater treatment technology that utilizes suspended plastic media to foster the growth of beneficial microorganisms for the biological treatment of sewage. MBBR is known for its efficiency, compact design, and versatility in handling various types of wastewater.

Overview

Moving Bed Biofilm Reactor (MBBR)

The Moving Bed Biofilm Reactor is a biological treatment process that enhances the efficiency of wastewater treatment by providing a large surface area for the colonization of microorganisms. This is achieved through the use of small plastic carriers or media that move freely within the reactor, creating a dynamic and highly effective environment for the biological treatment of organic pollutants.

Key Components and Operation:

Bioreactor Tank:

The heart of the MBBR system is the bioreactor tank, where wastewater,

oxygen, and suspended plastic media interact to facilitate the biological

treatment process.

Plastic Media:

Small plastic carriers, often in the form of floating discs or cylinders, are used

to provide a surface for the growth of biofilm. These carriers move freely

within the reactor, ensuring constant contact with the wastewater.

Microbial Biofilm:

Microorganisms, including bacteria and other microbes, form a biofilm on the

surface of the plastic media. This biofilm serves as a substrate for the

treatment of organic pollutants present in the wastewater.

Aeration System:

Aeration diffusers or other oxygenation mechanisms are employed to provide

the necessary oxygen for the microbial community to thrive and efficiently

metabolize organic matter.

Effluent Clarification:

After the biological treatment process, the treated water typically passes

through a clarifier or settling tank to separate the suspended solids and

biomass.

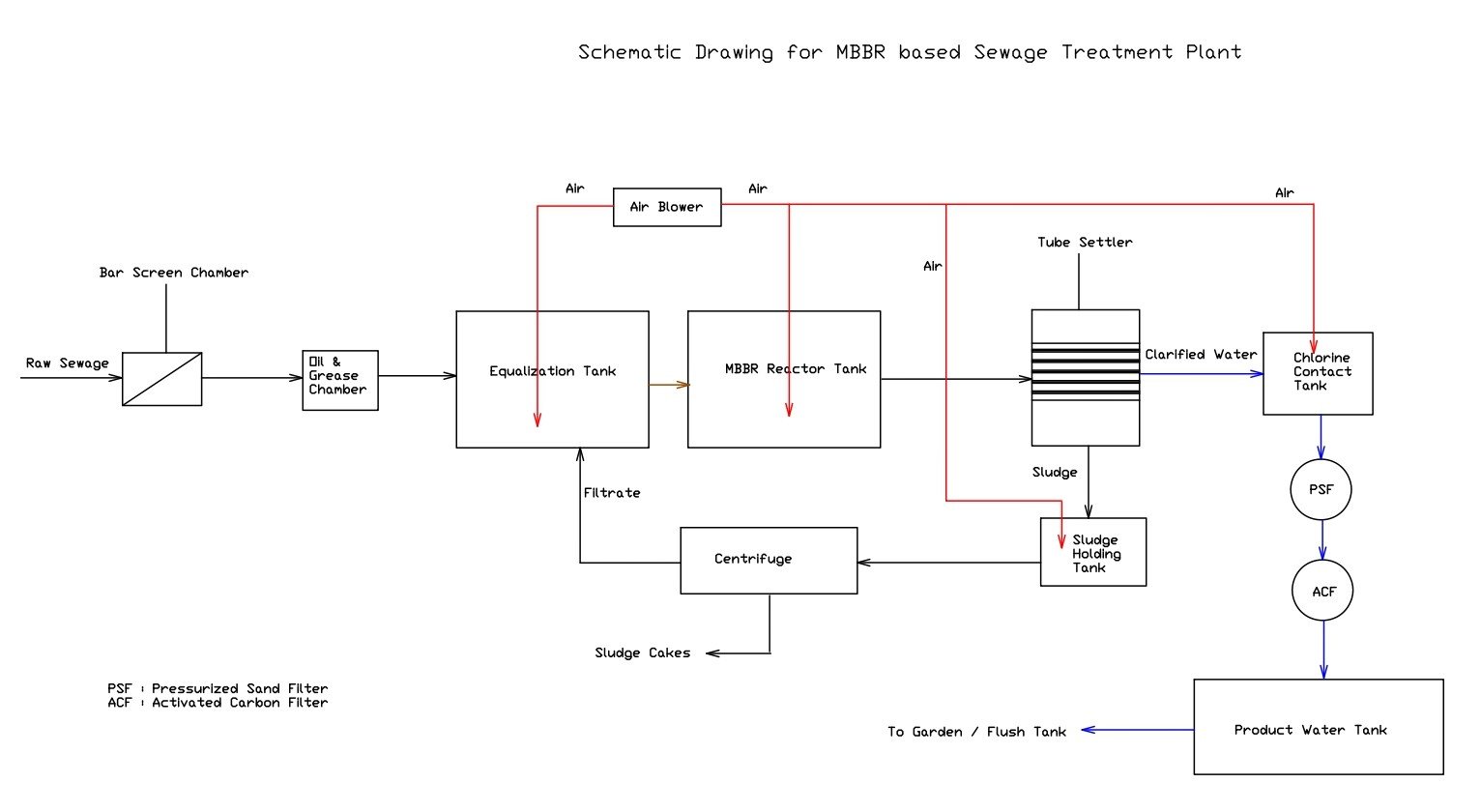

Schematic Block Diagram

Advantages

High Treatment Efficiency

The dynamic nature of the plastic media in constant motion allows for a highly efficient biological treatment process, leading to effective removal of organic pollutants.

Compact Design

MBBR systems are known for their compact design, making them suitable for installations with space constraints.

Versatility

MBBR technology is versatile and can be applied to various types of wastewater, including municipal sewage and industrial effluents.

Resilience to Load Fluctuations

The system is capable of handling variations in organic loads and hydraulic flow rates, providing flexibility in wastewater treatment operations.

Applications

Municipal Wastewater Treatment

SBRs are commonly used in small to medium-sized municipal treatment plants for their adaptability and efficiency.

01.

Industrial Wastewater Treatment

Industries with variable wastewater characteristics find SBRs advantageous due to their flexibility in handling different influent qualities.

02.

Decentralized and Containerized Systems

SBR technology is suitable for decentralized or containerized treatment systems, providing on-site solutions for specific applications.